Why You Need a Dual-Suction Powder Machine for Coating Hot Melt Powder on Heat Transfer Film

Why You Need a Dual-Suction Powder Machine for Hot Melt Powder on Heat Transfer Film

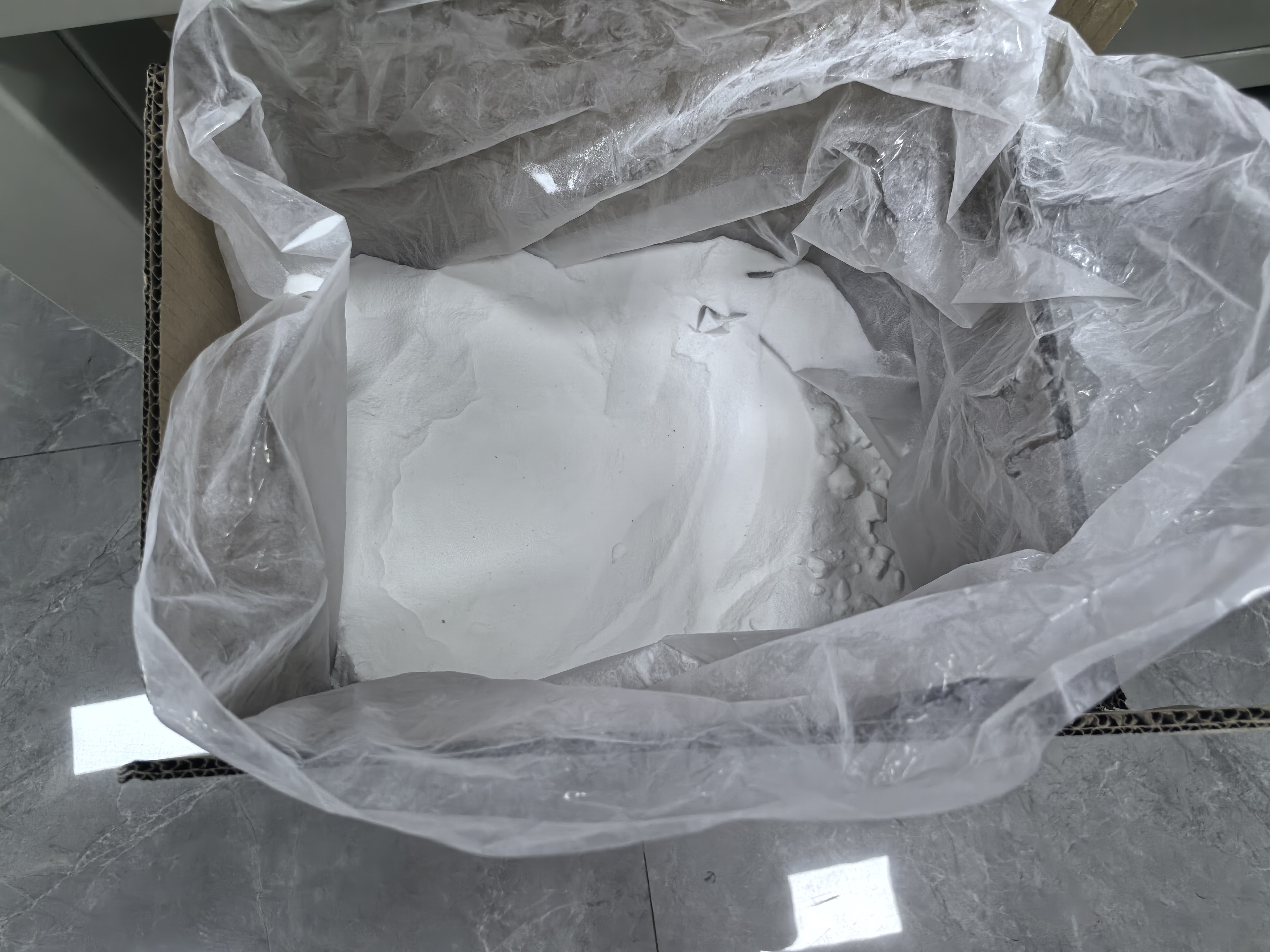

In the production of heat transfer films, achieving uniform application of hot melt powder is critical for high-quality results. TX-SF's Hot Melt Powder Coating Machine stands out as the ideal choice due to its unique dual-suction design and superior performance. Here’s why this equipment is indispensable for hot melt powder application.

1. High-Power Dual Suction for Residue-Free Powder Removal

1. High-Power Dual Suction for Residue-Free Powder Removal

1. High-Power Dual Suction for Residue-Free Powder Removal

During the powder coating process, excess hot melt powder that doesn’t adhere to the heat transfer film can create dust, polluting the workspace and wasting materials. The Hot Melt Powder Coating Machine’s dual-suction system features high-power suction to efficiently remove excess powder, ensuring a clean environment and compliance with environmental standards.

Advantage: Achieves over 90% recovery efficiency, ensuring zero powder residue.

2. Upper and Lower Suction Ports Prevent Scratches

Unlike single-suction machines, which rely on an upper suction port and a pressure roller that can scratch the film, the Hot Melt Powder Coating Machine uses upper and lower suction ports to securely hold the film in place without rollers. This prevents surface scratches and ensures product quality.

Advantage: Scratch-free film surface, reducing defect rates.

3.Precise Powder Application for Optimal Results

The quality of heat transfer films depends on uniform powder coating. The Hot Melt Powder Coating Machine allows precise control of powder application by adjusting the powder outlet size and regulator. By fine-tuning the outlet size and powder frequency, a dynamic balance is achieved for optimal coating consistency.

Advantage: Dynamic balance ensures uniform coating tailored to various film types.

4.Reduced Material Waste, Enhanced Cost Efficiency

The dual-suction design of the Hot Melt Powder Coating Machine not only controls dust but also recycles unattached powder for reuse, minimizing waste. This is critical for managing the high cost of hot melt powder, boosting overall cost efficiency.

Advantage: Up to 95% powder recovery rate, optimizing material usage.

5.Simplified Operation and Maintenance

The Hot Melt Powder Coating Machine features intuitive interfaces for easy operation. Its modular design simplifies cleaning and maintenance of the filtration and collection systems, reducing downtime.

Advantage: Modular structure ensures easy maintenance and long-term efficiency.

6. Durability and Reliable After-Sales Support

Heat transfer film production demands stable, long-term equipment performance. The Hot Melt Powder Coating Machine, built with high-strength materials, ensures durability and low failure rates. Coupled with reliable after-sales support, it guarantees production continuity.

Advantage: Minimum 1-year warranty with localized technical support.

Conclusion

With high-power dust control, scratch-free film handling, precise powder application, material efficiency, ease of use, and robust durability, TX-SF’s Hot Melt Powder Coating Machine is essential for heat transfer film production. It enhances quality, reduces costs, and minimizes environmental impact.

For more details, explore TX-SF’s Hot Melt Powder Coating Machine.