Which Shapes Work with Screen Printing Machines? A Simple Guide to Flat and Cylindrical Printing

Screen Printing on Flat and Curved Surfaces: A Simple Guide

Screen printing machines are great tools for factories. They help make clear prints on materials like glass, plastic, and metal.Screen printing machines can print on both flat and curved surfaces. As a top maker in China, we help factories create strong prints on many materials. This guide explains how it works for flat and curved items and what products you can make.

We’ll show you the best machines and tips to get started. Whether you’re new or growing, this will help you choose wisely.

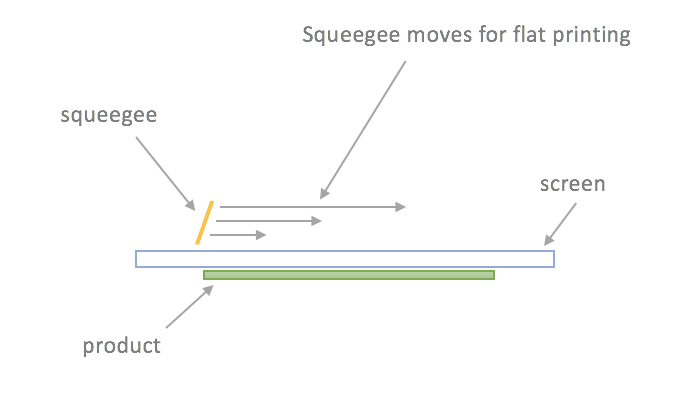

Flat Screen Printing: How It Works

How Flat Printing Works and Products It Fits

Flat printing uses a screen to push ink onto a flat surface. The item stays still on a table while the ink goes on. Our ST-series vertical screen printing machines are great for this. You can pick different tables based on your product.

Products: It works for flat glass, heat transfer film, PVC, PET film, cardboard, and more. Light items like sheets need a table with vacuum suction. Heavy boards work with a plain table. Tall tables fit boxes and metal sheets. T-slot tables are good for uneven flat items, like bent metal.

Tips:Choose the ST-series industrial screen printing machine. It's easy to adjust and fits many flat products, can make prints accurate to ±0.05mm, perfect for big, even designs.

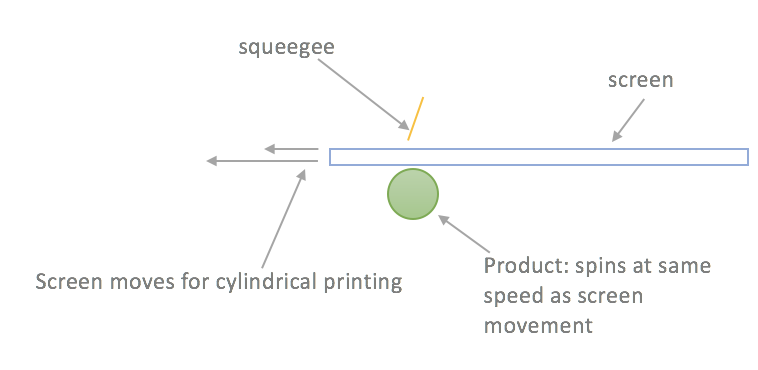

Curved Screen Printing: Printing All Around

How Curved Printing Works and Products It Fits

Curved printing allow the squeegee spins the item while the screen adds ink. This lets it print all the way around. It works because the machine turns the item smoothly. Our multi-color servo curved machines are best for this.

Products: It's perfect for milk tea cups, bottles, and cosmetic packaging. Curved surfaces are round, so you can't line them up like flat items. For multiple colors, use a machine with a color sensor and servo motor.

Tips: Pick a multi-color servo machine for bright, multi-color designs on curves.

Q1: Can flat machines handle slight curves?

A: Yes, with extra tools, but it's slower. Use a cylindrical screen printing machine for curves. We'll test it free.

Q2: What sizes fit cylindrical printing?

A: 10-300mm usually; bigger needs custom work (2 weeks).

Q3:Do you have a machine to print both flat and round surface?

A: Yes. we have the S/M series to print both flat and round surface, but switching takes time, we'll suggest flat printer to print flat and round printer to print round.

Conclusion and Tips: Pick the Right Machine

Screen printing works on flat and curved surfaces. Flat printing is simple for glass, film, and boards with the ST-series. Curved printing is great for cups and bottles with a servo machine. Test your products to find the best fit.

We suggest starting with the ST-series for flat items or S series machine for curves. Contact us for a free quote or watch factory video to see it work!